KINGROON 10KG PLA Matte 3D Printer Filament

Secure Payment Methods

All transactions are secure and encrypted

KINGROON 10KG PLA Matte 3D Printer Filament

Kingroon Matte PLA – Smooth, Soft, and Reliable

-

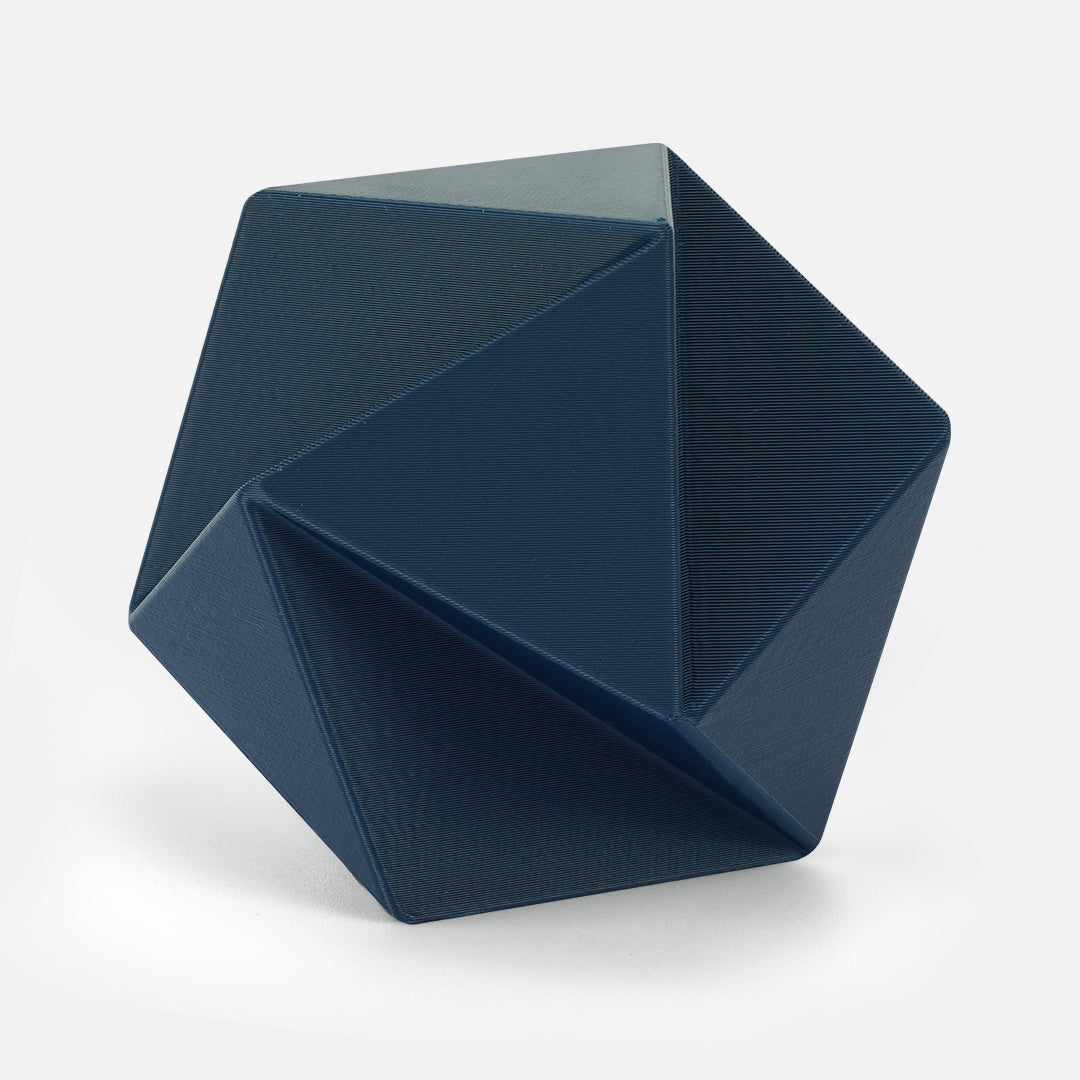

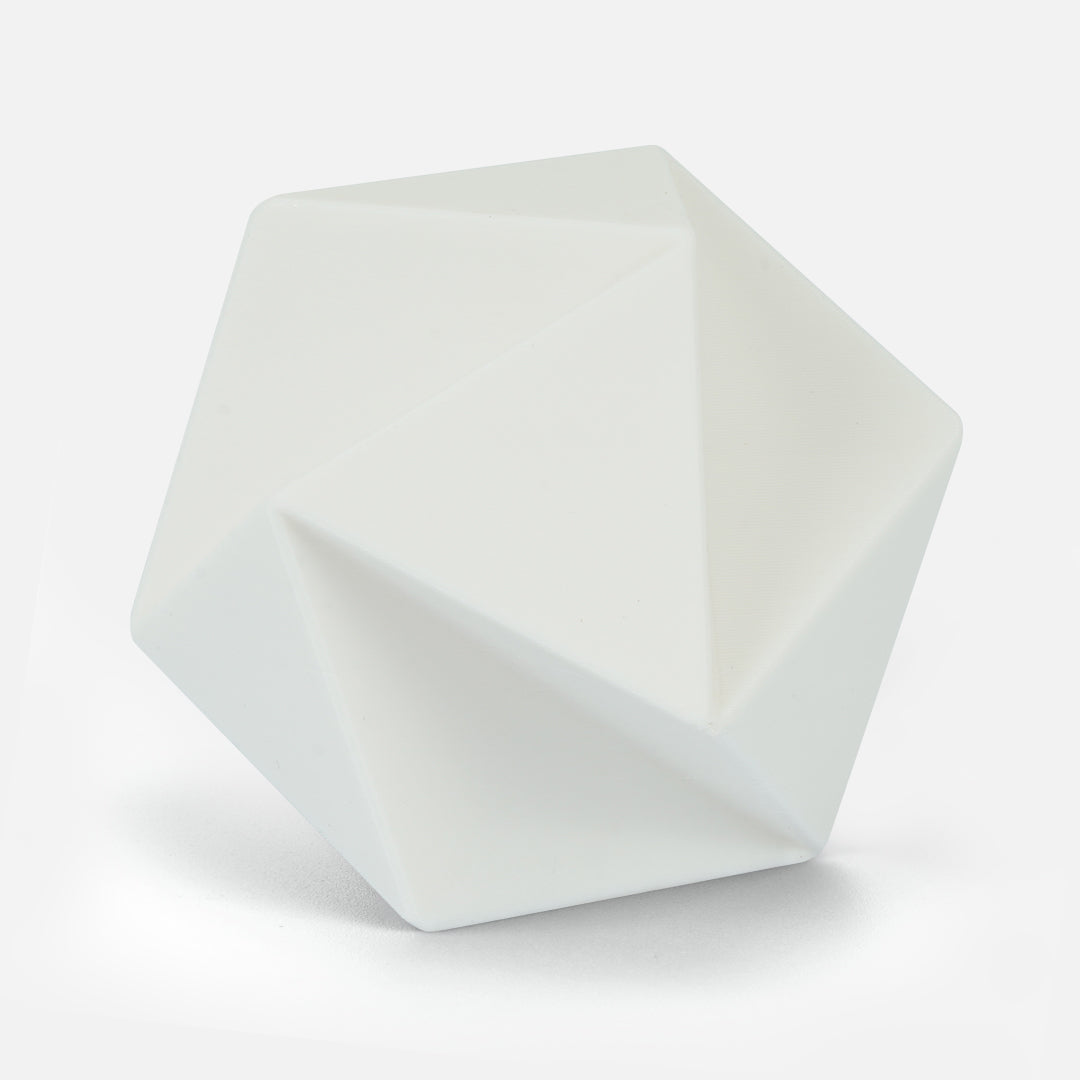

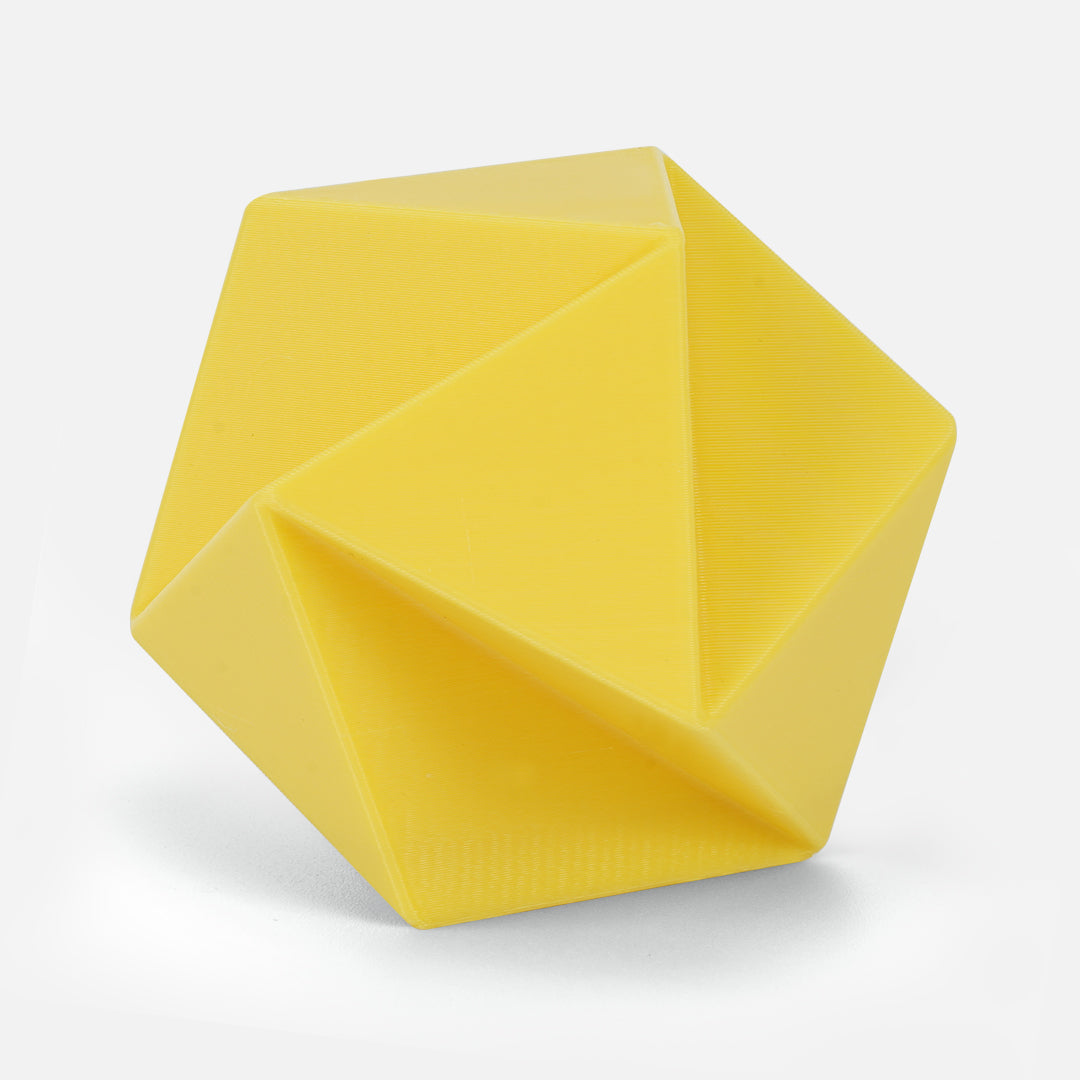

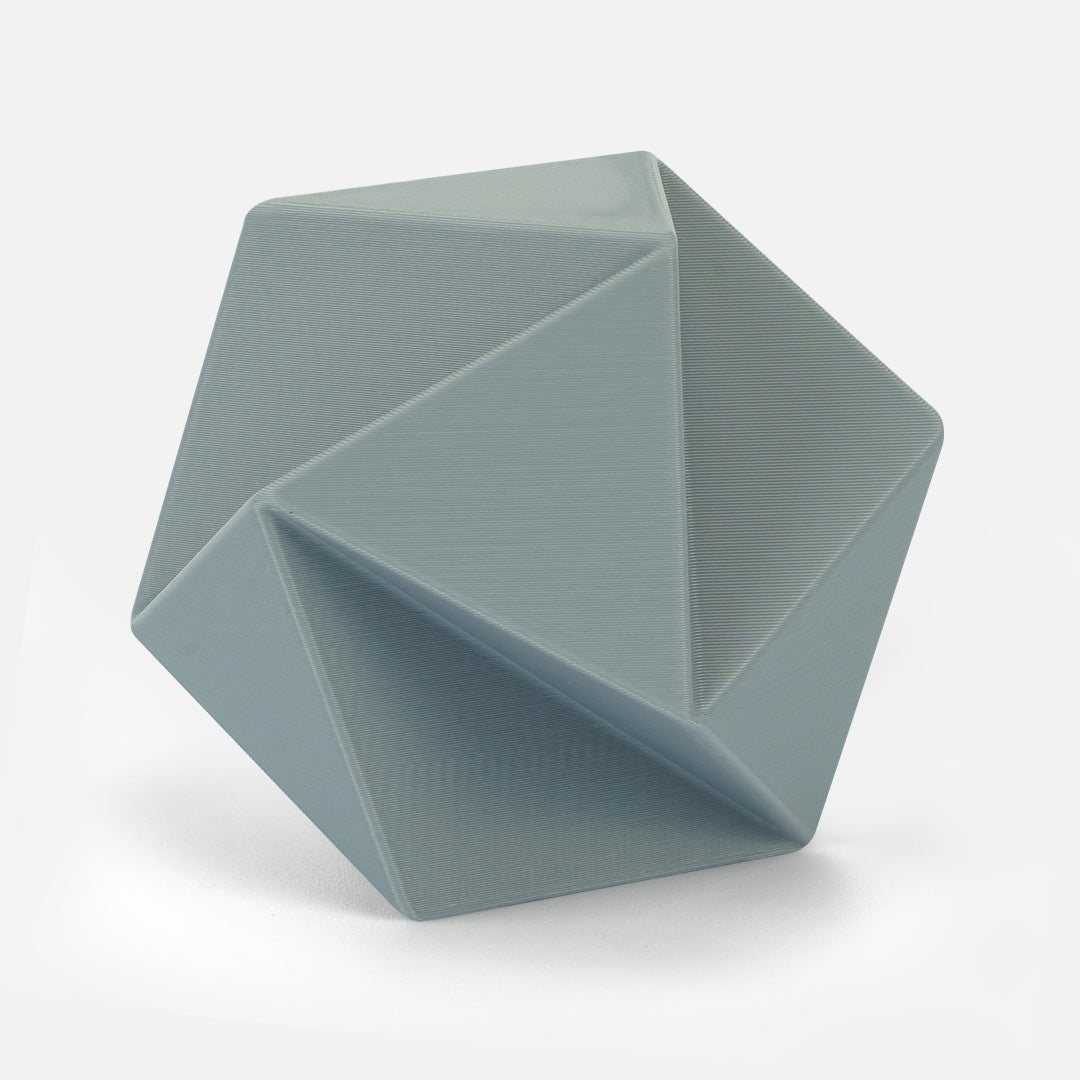

Beautiful Matte Finish: Kingroon Night Brown PLA produces a low-gloss, smooth matte surface, perfect for prints that require a soft, elegant texture.

-

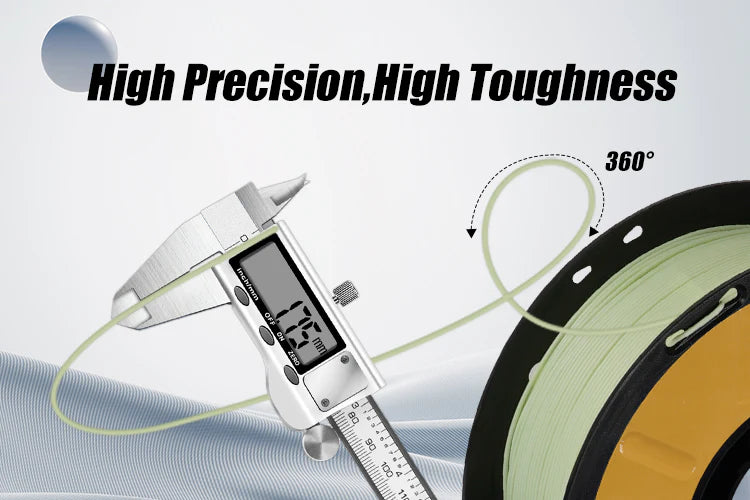

High Accuracy & Consistency: 1.75 mm diameter with ±0.02 mm tolerance ensures precise, reliable printing. Each 1 kg spool is compatible with nearly all 1.75 mm FDM 3D printers, delivering consistent feeding and stable results.

-

Optimal Printing Settings: For best results, use nozzle temperatures of 200–230 °C and a heated bed at 50–65 °C, ensuring smooth extrusion and strong layer adhesion.

-

Tangle-Free & Neatly Wound: Mechanical winding and inspection keep the filament neat, reducing breakage and ensuring smooth, uninterrupted feeding from the spool.

-

Clog-Free & Moisture-Protected: Each spool is dried for 24 hours and vacuum-sealed with a desiccant, preventing bubbles or clogs and providing stable, high-quality printing every time.

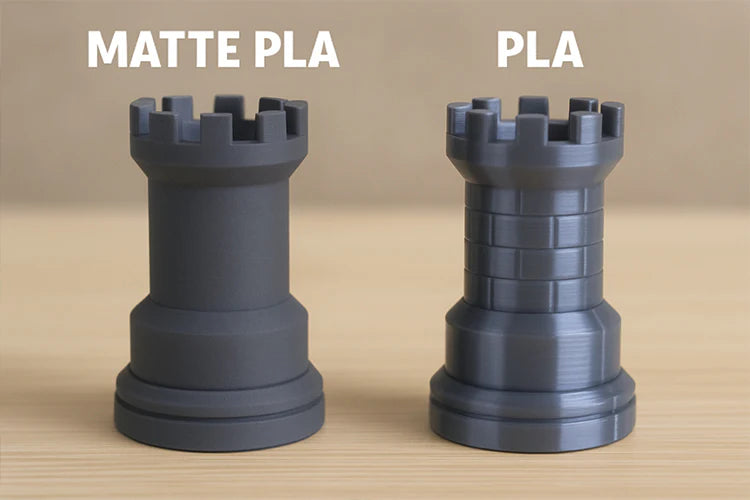

Matte Finish

Elegant matte finish that minimizes the visibility of layer lines

Premium Look

Achieves a professional, premium look for final products

Easy Print

Easy to print with minimal warping and good detail

Model Ready

Perfect for architectural models and aesthetic prototypes

Matte Finish

Upgrade your 3D prints with a smooth, non-reflective matte finish that hides layer lines and gives every model a premium look. Perfect for display pieces,functional parts, and prototypes, matte PLA delivers a clean,elegant aesthetic right offthe print bed-no post-processing needed.

High Dimensional Accuracy

Our matte PLA with Dimensional accuracy of +/- 0.02mm. Rigorous quality control ensures consistent filament dimensions,keeping your 3D printing tangle-free.

Neat Winding

Neat winding minimizes the filament tangle, ensuring a smooth printing experience.

Multi-color and Versatile

Featuring 16 uique lowsaturation colors and a smooth matte finish, Kingroon latte PLA is ideal for all kinds of projects art,fashion, gadgets, hobbies, toys, and tools. lnleash your 3D printing creativity!

3D printing material properties

Fully understand the printing settings, physical properties, and mechanical performance of the materials to optimize your 3D printing experience.

| Nozzle Temp(℃) | 200-230 |

|---|---|

| Bed Temp(℃) | 50-65 |

| Fan | 100% |

| Length | (1.75mm) 330-340m |

| Density | 1.31g/cm³ |

|---|---|

| Melt Index | 5-8(190℃/216kg)g/10min |

| Distortion Temp | 58℃(0.45MPa) |

| Izod impact strength | 5.9 kj/m² |

| Tensile strength | ≥ 42 MPa |

|---|---|

| Elongation at break | 0.1 |

| Bending strength | 80MPa |

| Flexural modulus | 2825MPa |

| Nozzle Temp(℃) | 200-230 |

|---|---|

| Bed Temp(℃) | 50-65 |

| Fan | 100% |

| Length | (1.75mm) 330-340m |

| Density | 1.31g/cm³ |

|---|---|

| Melt Index | 5-8(190℃/216kg)g/10min |

| Distortion Temp | 58℃(0.45MPa) |

| Izod impact strength | 5.9 kj/m² |

| Tensile strength | ≥ 42 MPa |

|---|---|

| Elongation at break | 0.1 |

| Bending strength | 80MPa |

| Flexural modulus | 2825MPa |

Recently Viewed Products

Printing Tips

Dry Before Use

Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer's heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use.

Filament drying instructions on WIKI →Using Refill Filament

The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

Spool refill guide on WIKI →