KINGROON PLA Silk Rainbow 3D Printer Filament

The picture is for reference only. Please adhere to the original products in case of any mistakes.some rolls are plastic while other are cardboard at random and it cant be chosen

KINGROON PLA Silk Rainbow 3D Printer Filament

Adored Chameleon Filament Series – Color-Changing PLA

Bring your 3D prints to life with the Chameleon series. This unique PLA filament changes color depending on light and viewing angles, thanks to specially engineered pigments that conceal layer lines for stunning visual effects. Available in five captivating shades: Burnt Titanium, Nebula Purple, Skydiver Blue, Rose Quartz, and Obsidian.

Ease of Use & Versatility

PLA is perfect for beginners and professionals alike. KINGROON PLA offers low printing temperatures, strong adhesion to common print surfaces, and high-quality raw materials for flawless results—even with default settings. Explore a variety of colors, including the Chameleon series, to bring your creative ideas to reality.

Low Warping & Minimal Odor

With low shrinkage and minimal warping, this filament delivers smooth, precise prints. Ideal for intricate designs, artistic pieces, and indoor use. Plus, it emits very little odor during printing, keeping your workspace comfortable.

Clog-Free & Bubble-Free

Designed for smooth, stable extrusion. Each spool is dried for 24 hours, vacuum-sealed, and quality-checked to ensure a reliable printing experience.

Precision & Consistency

Advanced CCD diameter measurement and adaptive control systems maintain a precise 1.75 mm diameter with ±0.02 mm tolerance. Each spool contains 1 kg (2.2 lbs) of premium PLA filament.

Rainbow Flow

Creates beautiful rainbow color gradients automatically

Silk Shine

Smooth silk finish with a brilliant, eye-catching gloss

Unique Touch

Each spool delivers vibrant and one-of-a-kind prints

Artistic Choice

Ideal for jewelry, decor, and creative projects

Neat Winding

Neat winding minimizes the filament tangle, ensuring a smooth printing experience.

High Accuracy and Quality

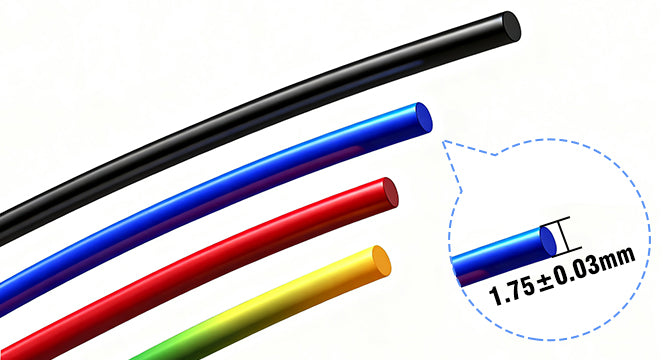

Dimensional accuracy of +/- 0.03mm. Rigorous quality control ensures consistent filament dimensions, keeping your 3D printing tangle-free

Glossy Silk Finish

High quality silk PLA print in glossy and smooth finish objects, Giving you special touch feeling.

Your Go-To for Everyday Creativity

A versatile and eco-friendly material perfect for prototyping, models, and daily creations.

3D printing material properties

Fully understand the printing settings, physical properties, and mechanical performance of the materials to optimize your 3D printing experience.

| Nozzle Temp(℃) | 195-230 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Density | 1.21g/cm³ |

|---|---|

| Melt Index | 12.8(190℃/216kg)g/10min |

| Distortion Temp | 50℃(0.45MPa) |

| Izod impact strength | 5.8kj/m² |

| Tensile strength | ≥ 52MPa |

|---|---|

| Elongation at break | 0.142 |

| Bending strength | 65MPa |

| Flexural modulus | 1440MPa |

| Nozzle Temp(℃) | 195-230 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Density | 1.21g/cm³ |

|---|---|

| Melt Index | 12.8(190℃/216kg)g/10min |

| Distortion Temp | 50℃(0.45MPa) |

| Izod impact strength | 5.8kj/m² |

| Tensile strength | ≥ 52MPa |

|---|---|

| Elongation at break | 0.142 |

| Bending strength | 65MPa |

| Flexural modulus | 1440MPa |

Printing Tips

Dry Before Use

Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer's heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use.

Filament drying instructions on WIKI →Using Refill Filament

The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

Spool refill guide on WIKI →