KINGROON 10KG PLA Silk Dual Color 3D Printer Filament

The picture is for reference only. Please adhere to the original products in case of any mistakes.some rolls are plastic while other are cardboard at random and it cant be chosen

KINGROON 10KG PLA Silk Dual Color 3D Printer Filament

Silk-Like Appearance with Gradient Glow:

KINGROON Silk Dual-Color PLA is produced with an advanced triple dual-extrusion process, blending two or three colors along the spool. Printed models feature a smooth, silk-like texture with vibrant gradient effects, producing luminous, eye-catching results.

Complete Compatibility & Easy to Print:

Engineered for wide temperature and speed ranges, this filament works seamlessly with most mainstream FDM printers. Its versatility ensures optimal printing results regardless of printer model or settings.

Strong Adhesion for Reliable Prints:

KINGROON Silk Dual-Color PLA offers excellent first-layer adhesion, minimizing warping, shrinkage, and curling. Enjoy a smooth, stress-free printing experience with higher success rates for detailed and complex models.

Clog-Free & Bubble-Free:

Each spool is vacuum-sealed with built-in desiccant to prevent moisture absorption, ensuring clean, consistent extrusion without bubbles or flow interruptions.

Wide Printer Compatibility:

Neatly wound with consistent dimensions, the filament has a 1.75 mm diameter with ±0.02 mm tolerance, ensuring compatibility with nearly all FDM 3D printers.

Stunning Silk

Creates smooth, shiny models with a silky finish

Vibrant Colors

Tri-color effect adds depth and dimension to your prints

Easy Printing

Minimal warping with excellent layer adhesion

Creative Fun

Perfect for decorative items, prototypes, and artistic creations

High precision & premium quality

Produces a stunning high-gloss, silk-like finish with a captivating tri-color effect that changes in the light.

High Accuracy and Quality

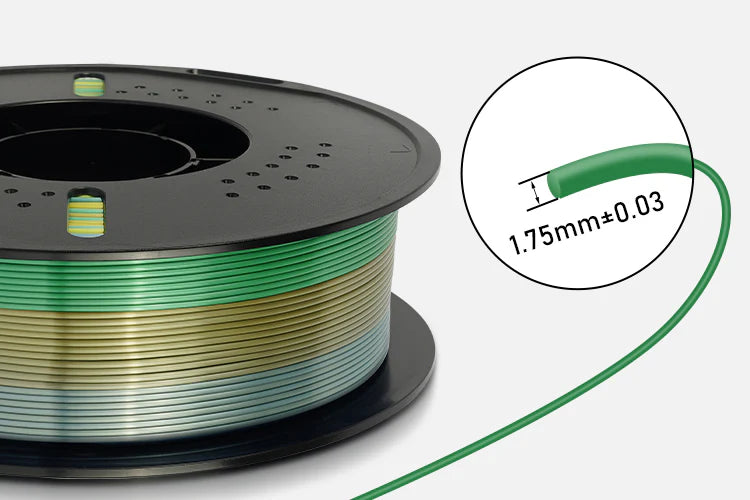

Dimensional accuracy of +/- 0.03mm. Rigorous quality control ensures consistent filament dimensions, keeping your 3D printing tangle-free.

Nicely Packed & Neatly Wound

Expertly engineered Silk PLA filament with evenly wound spools and tangle-free packaging. Smooth, consistent feed for flawless prints and exceptional success every time.

Your Go-To for Everyday Creativity

A versatile and eco-friendly material perfect for prototyping, models, and daily creations.

3D Printer Filament

Fully understand the printing settings, physical properties, and mechanical performance of the materials to optimize your 3D printing experience.

| Nozzle Temp(℃) | 195-230 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Density | 1.2g/cm³ |

|---|---|

| Melt Index | 12.8(190℃/216kg)g/10min |

| Distortion Temp | 53℃(0.45MPa) |

| Izod impact strength | 3.9kj/m² |

| Tensile strength | ≥ 55MPa |

|---|---|

| Elongation at break | 0.198 |

| Bending strength | 68MPa |

| Flexural modulus | 1650MPa |

| Nozzle Temp(℃) | 195-230 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Density | 1.2g/cm³ |

|---|---|

| Melt Index | 12.8(190℃/216kg)g/10min |

| Distortion Temp | 53℃(0.45MPa) |

| Izod impact strength | 3.9kj/m² |

| Tensile strength | ≥ 55MPa |

|---|---|

| Elongation at break | 0.198 |

| Bending strength | 68MPa |

| Flexural modulus | 1650MPa |

Printing Tips

Dry Before Use

Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer's heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use.

Filament drying instructions on WIKI →Using Refill Filament

The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

Spool refill guide on WIKI →