KINGROON PETG Carbon Fiber Basic 3D Printer Filament

The picture is for reference only. Please adhere to the original products in case of any mistakes.some rolls are plastic while other are cardboard at random and it cant be chosen

KINGROON PETG Carbon Fiber Basic 3D Printer Filament

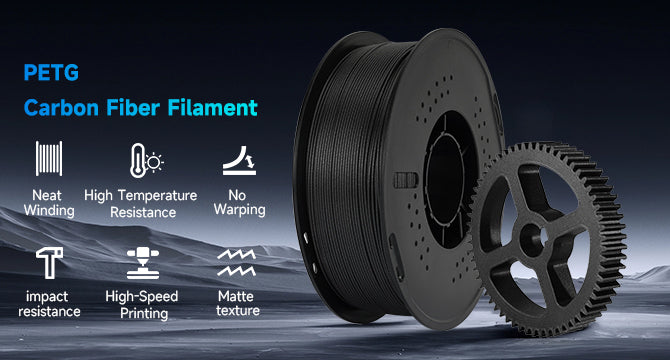

Premium Carbon Fiber Reinforced PETG:

KINGROON Carbon Fiber PETG is reinforced with premium carbon fibers, enhancing material strength and heat resistance while retaining the excellent impact resistance of standard PETG. Ideal for functional and industrial-grade 3D prints.

Stable & Reliable Printing:

Engineered for rigidity, dimensional stability, and smooth surface quality. Perfect for frames, drones, tools, automotive parts, and other demanding applications where performance matters.

Clog-Free & Bubble-Free:

Manufactured using clog-resistant methods, thoroughly dried for 24 hours, and vacuum-sealed with desiccant to prevent moisture absorption. Ensures smooth, consistent extrusion and precise printing results.

Tangle-Free & Easy to Use:

Each spool is mechanically wound and manually inspected to ensure neat, tangle-free filament. Enhanced flowability provides reliable feeding, compatible with 99% of FDM 3D printers.

Excellent Customer Support:

KINGROON Carbon Fiber PETG comes with reliable after-sales support. Our team provides prompt 24-hour online service to assist with any product questions or concerns.

Carbon Reinforced

Superior stiffness and strength with carbon fiber

Matte Finish

High-quality technical matte surface look

Light & Rigid

Perfect for strong, lightweight components

Pro Setup

Use a hardened steel nozzle for best results

Enhanced Rigidity for Structural Parts

Offers superior stiffness and strength over standard PLA for brackets and tools.

Easy to print, Well formed

High temperature resistancetensile strengthhigh impact strengthexcellent mechanical properties

High Accuracy and Quality

Dimensional accuracy of +/- 0.03mm. Rigorous quality control ensures consistent filament dimensions, keeping your 3D printing tangle-free.

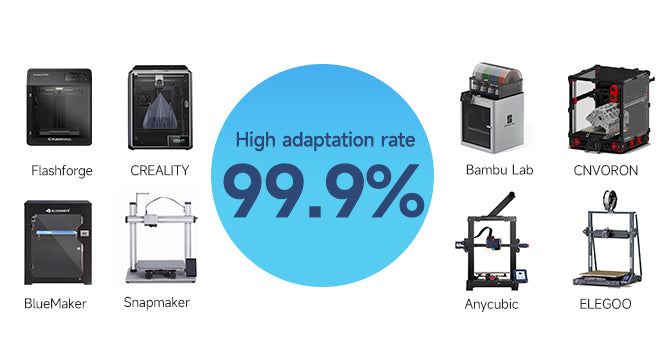

Universal Printer Fit

Compatible with 99.9% of leading 3D printers. Smooth, stable printing with zero hassle

3D printing material properties

Fully understand the printing settings, physical properties, and mechanical performance of the materials to optimize your 3D printing experience.

| Nozzle Temp(℃) | 190-220 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Tensile strength | ≥ 30MPa |

|---|---|

| Elongation at break | 0.062 |

| Bending strength | 36MPa |

| Flexural modulus | 2850MPa |

| Tensile strength | ≥ 34MPa |

|---|---|

| Elongation at break | 6.8 |

| Bending strength | 0% |

| Flexural modulus | 0 |

| Nozzle Temp(℃) | 190-220 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Tensile strength | ≥ 30MPa |

|---|---|

| Elongation at break | 0.062 |

| Bending strength | 36MPa |

| Flexural modulus | 2850MPa |

| Tensile strength | ≥ 34MPa |

|---|---|

| Elongation at break | 6.8 |

| Bending strength | 0% |

| Flexural modulus | 0 |

Printing Tips

Dry Before Use

Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer's heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use.

Filament drying instructions on WIKI →Using Refill Filament

The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

Spool refill guide on WIKI →