KINGROON PLA Glow-in-the-dark 3D Printer Filament

The picture is for reference only. Please adhere to the original products in case of any mistakes.some rolls are plastic while other are cardboard at random and it cant be chosen

KINGROON PLA Glow-in-the-dark 3D Printer Filament

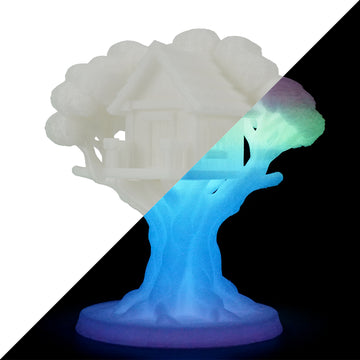

Amazing Glow Effect:

KINGROON Glow-in-the-Dark PLA contains premium glow powders that emit a bright, fantastic light after absorbing energy. Glow intensity is strongest under UV light, followed by sunlight and LED light. For best results, expose your prints to strong sunlight or UV light for about 30 minutes before enjoying the glow effect.

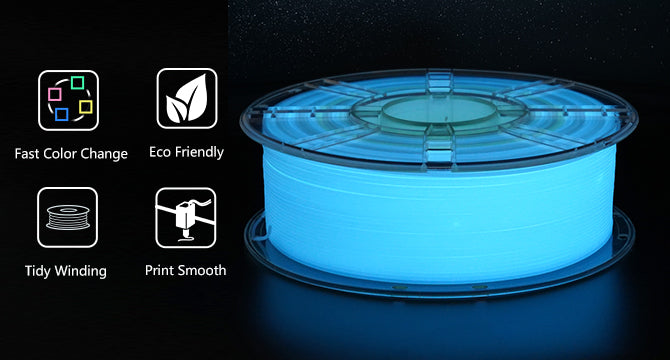

High-Quality PLA:

Made from premium raw materials, KINGROON PLA offers excellent printability with good ductility, high strength, and minimal warping. Odor-free, clog-free, and bubble-free. Each spool is fully dried for 24 hours and mechanically wound to prevent tangles and knots, making printing smooth and reliable.

Precision Diameter – 1.75 mm:

Advanced CCD diameter control ensures a tight ±0.03 mm tolerance, providing stable and consistent extrusion. Recommended printing settings: Nozzle 190–220 °C, Bed 50–60 °C, Print Speed 30–90 mm/s.

Wide Printer Compatibility:

Works with nearly all FDM 3D printers. The spool features a large inner diameter for smoother feeding. Spool dimensions: Diameter 7.99 in, Width 2.48 in, Hub Hole 2.36 in. (Plastic spool now standard for maximum compatibility.)

What You Will Get:

Each package includes 1 kg (2.2 lbs) glow-in-the-dark PLA, a resealable bag, a 5 m cleaning filament, a 5 m random filament sample, and friendly customer support. If you have any questions or suggestions, our team is ready to assist you.

Strong Build

Increased impact resistance and mechanical strength

Tight Bond

Superior layer bonding reduces splitting and breaking

Easy Print

Retains the easy printability of standard PLA+

Best Choice

The best choice for functional prototypes and parts

Eco-friendly

Kingroon PLA filament is made from plant-based starches like corn and cassava. This renewable, plant-based material is biodegradable and eco-friendly, posing no harm to the environment.

Charge It Up, Light It Up

Absorbs light to emit a bright, long-lasting glow, transforming prints into magical, luminous objects.

100% No Tangle

Machine Auto Wind, Fixed Hole Steady

Easy to Print, Amazing to See

Achieves stunning glowing results with standard PLA settings, no complicated hurdles.

3D Printer Filament

Fully understand the printing settings, physical properties, and mechanical performance of the materials to optimize your 3D printing experience.

| Nozzle Temp(℃) | 200-220 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Density | 1.23g/cm³ |

|---|---|

| Melt Index | 14(190℃/216kg)g/10min |

| Distortion Temp | 53℃(0.45MPa) |

| Izod impact strength | 5.4kj/m² |

| Tensile strength | ≥ 50MPa |

|---|---|

| Elongation at break | 0.112 |

| Bending strength | 91MPa |

| Flexural modulus | 1913MPa |

| Nozzle Temp(℃) | 200-220 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 100% |

| Length | (1.75mm) 330-335m |

| Density | 1.23g/cm³ |

|---|---|

| Melt Index | 14(190℃/216kg)g/10min |

| Distortion Temp | 53℃(0.45MPa) |

| Izod impact strength | 5.4kj/m² |

| Tensile strength | ≥ 50MPa |

|---|---|

| Elongation at break | 0.112 |

| Bending strength | 91MPa |

| Flexural modulus | 1913MPa |

Printing Tips

Dry Before Use

Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer's heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use.

Filament drying instructions on WIKI →Using Refill Filament

The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

Spool refill guide on WIKI →