KINGROON PETG Basic 3D Printer Filament

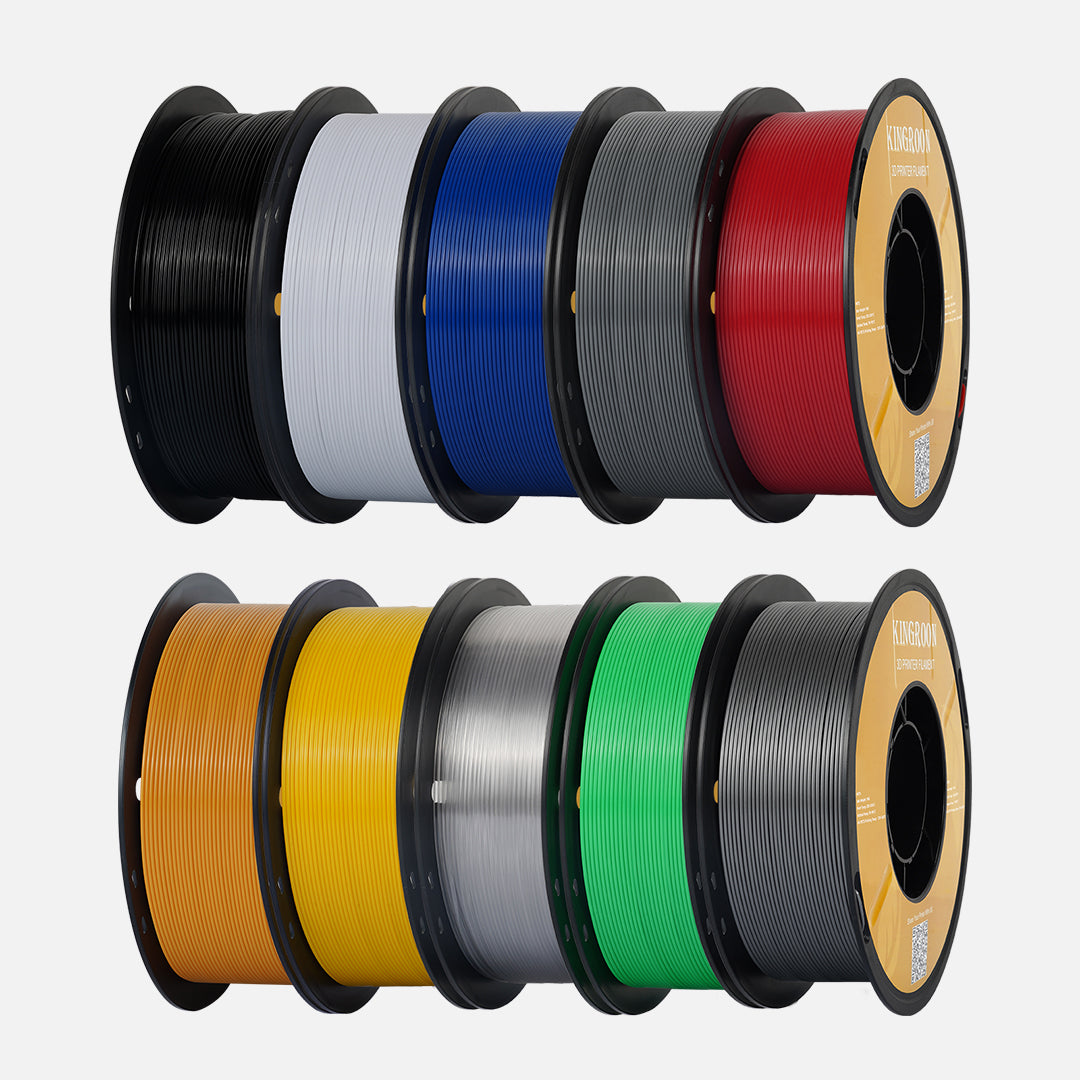

The picture is for reference only. Please adhere to the original products in case of any mistakes.some rolls are plastic while other are cardboard at random and it cant be chosen

KINGROON PETG Basic 3D Printer Filament

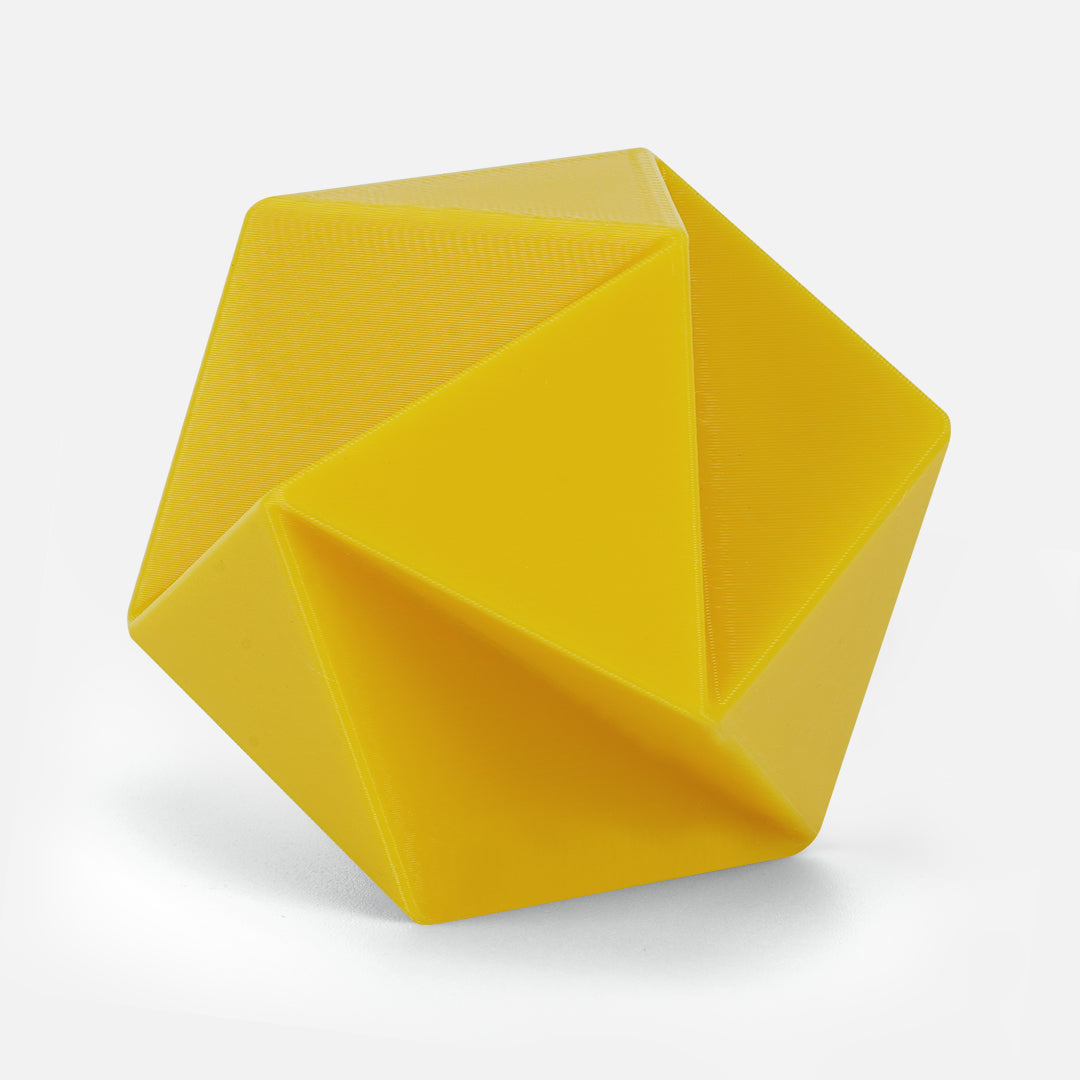

Strong Print

Combines ease of printing with strength and durability

Heat Tough

Good heat resistance and toughness for functional parts

Low Warp

Low shrinkage and warping for reliable printing

Resistant Use

Water and chemical resistant for outdoor and utility use

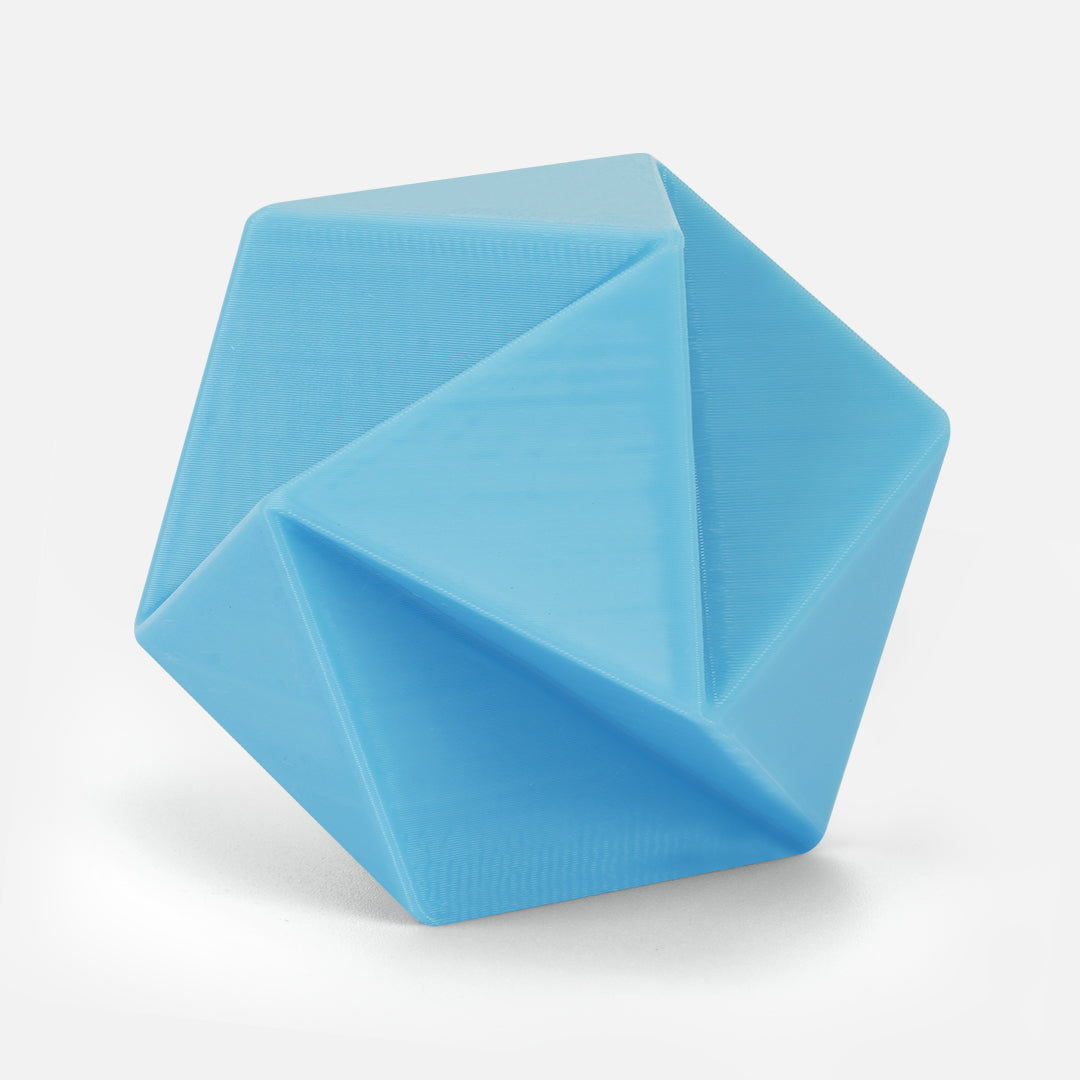

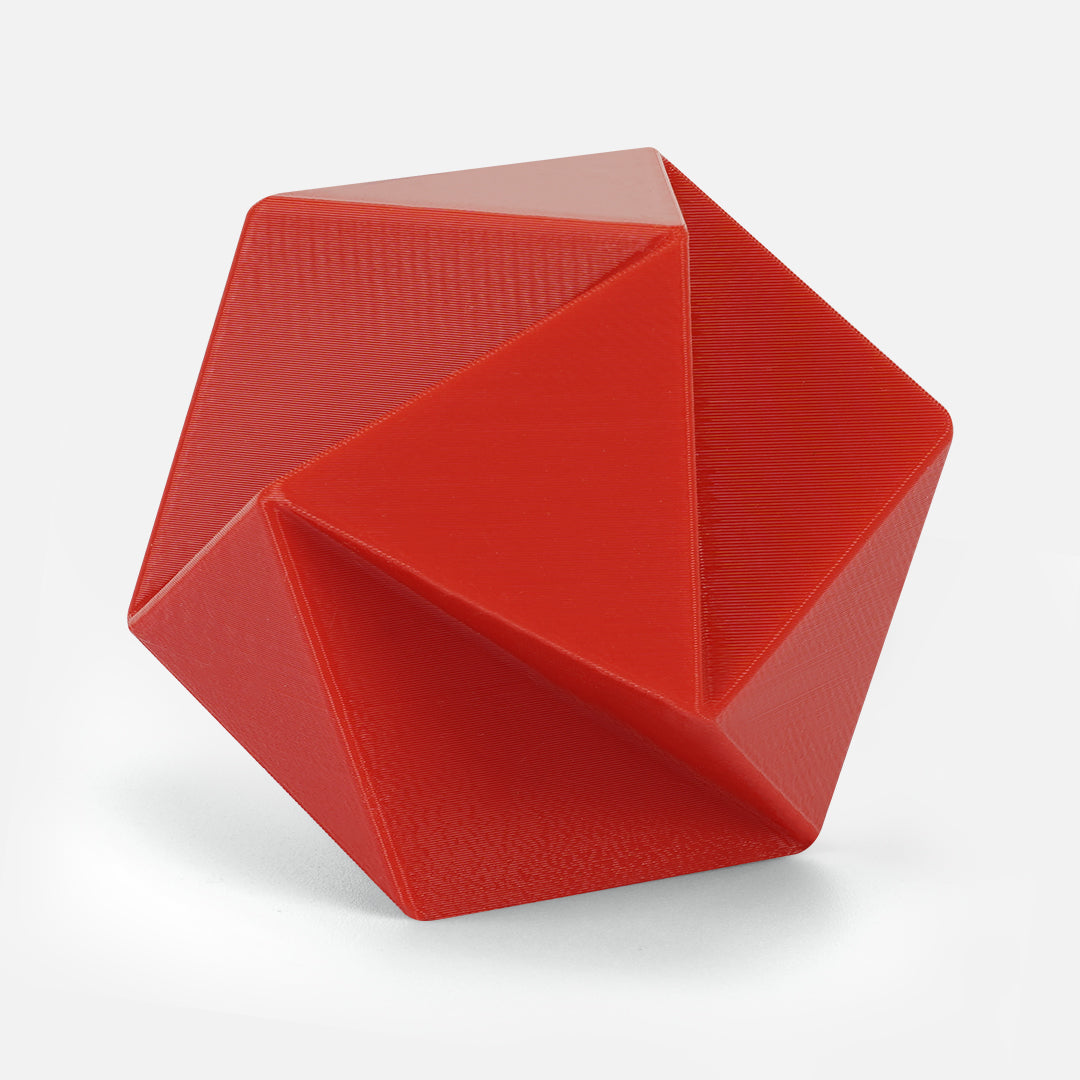

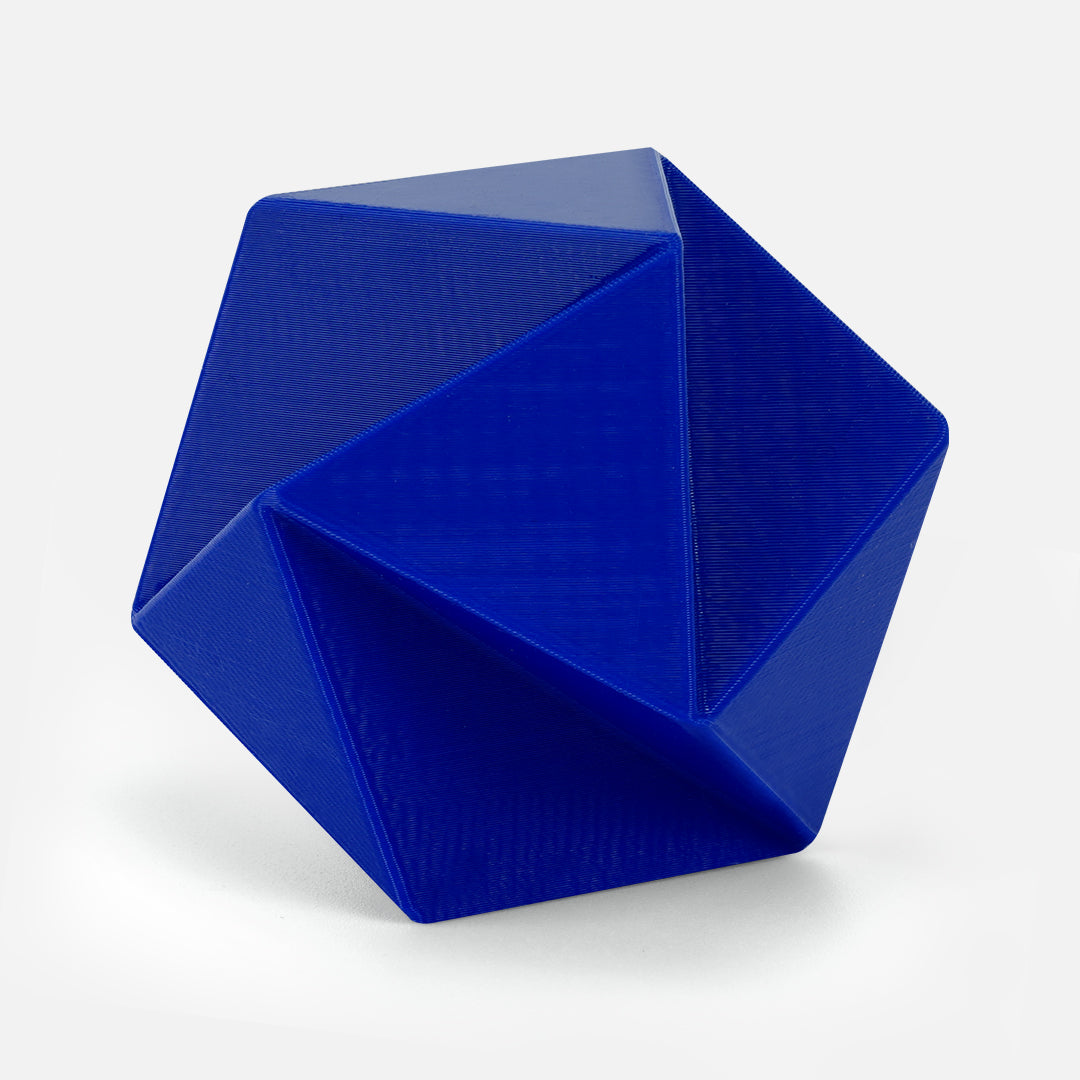

High strength and Durable

Kingroon PETG is more impact-resistant and tougher, making it ideal for engineering and functional parts in 3D printing.

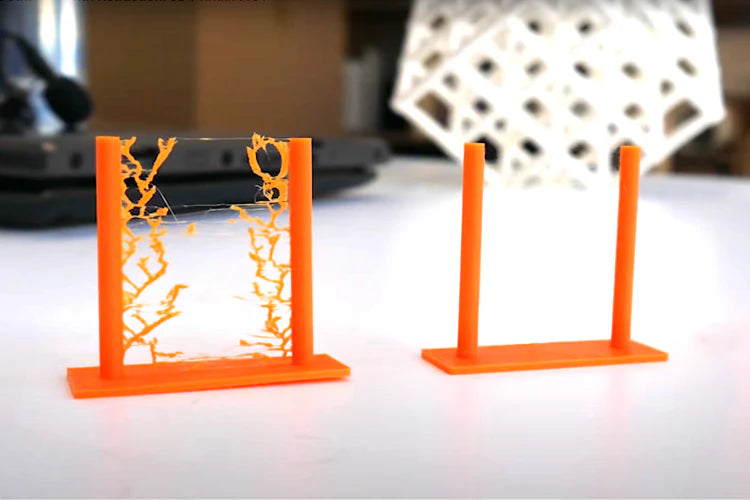

Less stringing and clumping

The modified formula Kingroon PETG reduces clumping, oozing, and stringing issues during printing.

Vibrant Color Selection

Choose from our extensive palette of vibrant, consistent colors that maintain their appearance after printing.

Our specialized pigment formulation ensures color uniformity throughout the spool and between batches.

Vibrant Color Selection

Choose from our extensive palette of vibrant, consistent colors that maintain their appearance after printing.

3D printing material properties

Fully understand the printing settings, physical properties, and mechanical performance of the materials to optimize your 3D printing experience.

| Nozzle Temp(℃) | 230-250 |

|---|---|

| Bed Temp(℃) | 70-90 |

| Fan | 100% |

| Length | (1.75mm) 330-340m |

| Density | 1.26g/cm³ |

|---|---|

| Melt Index | 20(250C/2.16kg)g/10min |

| Distortion Temp | 62℃(0.45MPa) |

| Izod impact strength | 4.7kj/m² |

| Tensile strength | ≥ 50MPa |

|---|---|

| Elongation at break | 0.82 |

| Bending strength | 65MPa |

| Flexural modulus | 1078MPa |

| Nozzle Temp(℃) | 230-250 |

|---|---|

| Bed Temp(℃) | 70-90 |

| Fan | 100% |

| Length | (1.75mm) 330-340m |

| Density | 1.26g/cm³ |

|---|---|

| Melt Index | 20(250C/2.16kg)g/10min |

| Distortion Temp | 62℃(0.45MPa) |

| Izod impact strength | 4.7kj/m² |

| Tensile strength | ≥ 50MPa |

|---|---|

| Elongation at break | 0.82 |

| Bending strength | 65MPa |

| Flexural modulus | 1078MPa |

Printing Tips

Dry Before Use

Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer's heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use.

Filament drying instructions on WIKI →Using Refill Filament

The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

Spool refill guide on WIKI →