KINGROON TPU Basic 3D Printer Filament

The picture is for reference only. Please adhere to the original products in case of any mistakes.some rolls are plastic while other are cardboard at random and it cant be chosen

KINGROON TPU Basic 3D Printer Filament

High-Quality TPU Material

Made for durability and flexibility. With a Shore hardness of 95A, this TPU filament offers the perfect balance of softness and strength—ideal for flexible parts, wearables, robotics, and creative fashion projects.

Excellent Layer Adhesion

Ensures strong, consistent prints. The optimized formula delivers reliable layer bonding and a smooth, uniform surface finish.

Clog-Free & Bubble-Free

Manufactured with a patented clog-free formulation for stable and seamless extrusion. Each spool is dried for 24 hours and vacuum-sealed in a resealable foil bag. For best results, store TPU with desiccants or dry for over 8 hours at 65°C before use.

Wide Compatibility & Color Options

Works with most consumer and industrial 3D printers. Available in a wide range of vibrant colors to support any creative or functional project.

Reliable & Supported Printing

Includes dedicated customer support and a 1-year shelf life for unopened spools (with proper storage). A dependable TPU filament designed to deliver smooth, hassle-free prints.

Flex Shield

High flexibility and elasticity for shock absorption

Tough Bond

Excellent layer adhesion creates durable, tear-resistant parts

Wear Guard

Good abrasion, maintains flexibility even in cold

All-Rounder

Perfect for phone cases, gaskets, seals, and tires

High elasticity and softness

Kingroon TPU 95A – Soft, Flexible & Highly Elastic for Realistic Bounce Exceptional Impact Resistance – Perfect for Protective Covers, Mats & More

Neat Winding

Neat winding minimizes the filament tangle, ensuring a smooth printing experience.

Broad Applications

TPU – Perfect for phone cases, gaskets, footwear & more Strong impact resistance for protective gear, automotive & industrial parts

Oil Resistance and Weather Resistance

Kingroon TPU – Highly resistant to oils, lubricants & solvents Strong weatherproofing with excellent UV durability for long-lasting use

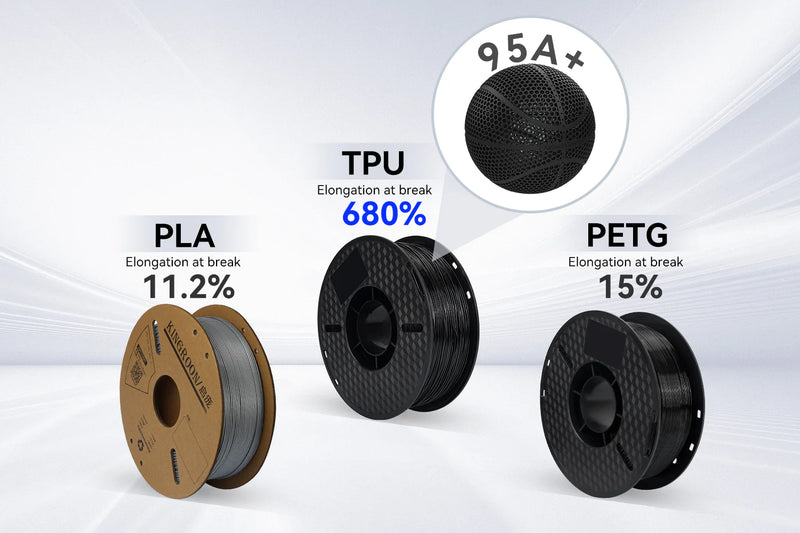

3D printing material properties

Fully understand the printing settings, physical properties, and mechanical performance of the materials to optimize your 3D printing experience.

| Nozzle Temp(℃) | 200-230 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 0% |

| Length | (1.75mm) 330-340m |

| Density | 1.21g/cm³ |

|---|---|

| Melt Index | 1.2(190℃/2.16kg) |

| Distortion Temp | 0% |

| Izod impact strength | 0 |

| Tensile strength | ≥ 34MPa |

|---|---|

| Elongation at break | 6.8 |

| Bending strength | 0% |

| Flexural modulus | 0 |

| Nozzle Temp(℃) | 200-230 |

|---|---|

| Bed Temp(℃) | 50-70 |

| Fan | 0% |

| Length | (1.75mm) 330-340m |

| Density | 1.21g/cm³ |

|---|---|

| Melt Index | 1.2(190℃/2.16kg) |

| Distortion Temp | 0% |

| Izod impact strength | 0 |

| Tensile strength | ≥ 34MPa |

|---|---|

| Elongation at break | 6.8 |

| Bending strength | 0% |

| Flexural modulus | 0 |

Printing Tips

Dry Before Use

Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer's heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use.

Filament drying instructions on WIKI →Using Refill Filament

The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

Spool refill guide on WIKI →